PRODUCTS

Products, non-standard customization

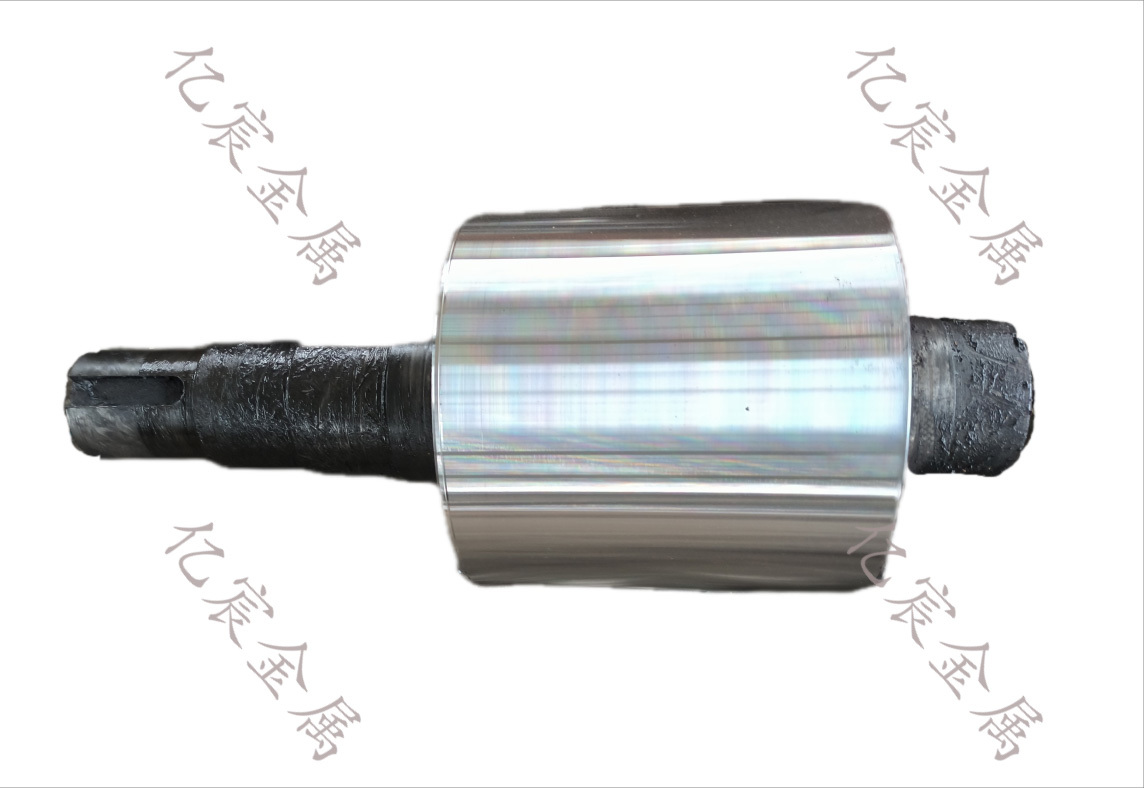

Main products:Hot-rolled copper rolls, hot-rolled aluminum (alloy) rolls, hot-rolled billet rolls of various specifications such as piercing mill rolls, rolling mill rolls, sizing rolls, continuous rolls, mandrels, guide plates, jacks, etc., hot-rolled billet rolls of steel mills, cold-rolled support rolls, power plant coal grinding rolls, various medium-cold roll surface surfacing welding insert sleeve treatment, as well as frame and frame accessories and other products.

ABOUT US

Cangzhou Yichen Metal Rolling Equipment Co., Ltd.

Cangzhou Yichen Metal Rolling Equipment Co., Ltd. is a manufacturing, processing, sales in one of the enterprises. The company is located in the eastern part of Hebei, on the banks of the South Canal, and in Nanpi County, Gupi City. It is 250 kilometers from Beijing to the north, l60 kilometers from Tianjin, 200 kilometers from Jinan to the south, 180 kilometers from Tianjin Port to the east, 80 kilometers from Huanghua Port and 220 kilometers from Shijiazhuang to the west. The Beijing-Shanghai Railway and the Beijing-Shanghai Expressway pass through the border. Roads, railways, water transportation, and air transportation are developed.

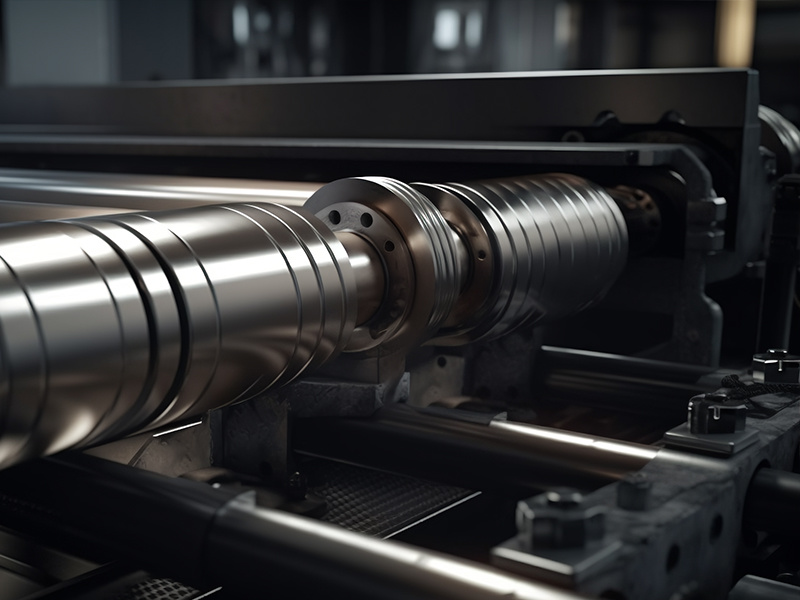

The company mainly produces hot-rolled seamless steel pipe equipment, various alloy ductile iron, casting rolls, high wear resistance and corrosion resistance rolls, high nickel chromium molybdenum roll rings, special steel rolls, mechanical design and manufacturing, etc. Take the lead through the international quality management system 9000, high-tech enterprises, Hebei science and technology small and medium-sized enterprises, various technology patents and other certification.

Annual Productivity Roll

Various production equipment

Floor Area

CUSTOMIZED

Support non-standard custom production

It mainly produces hot-rolled copper rolls, hot-rolled aluminum (alloy) rolls, hot-rolled billet rolls, cold-rolled support rolls, power plant coal grinding rolls, various medium-cold rolls surfacing treatment, as well as frame and frame accessories and other products of various specifications such as piercing mill rolls, rolling mill rolls, sizing rolls, continuous rolls, mandrel bars, guide plates, plug heads, etc.

Advanced equipment, modern management, high-quality steel raw materials

With our professional R & D team and engineers, we create innovative solutions for the needs of our business partners

Strong technical force, complete testing means, can be on behalf of the user product demand design, to provide technical solutions

RECOMMEND

recommend products

Metal guide plate commonly used metal materials include carbon

The working principle of the sizing roller is to use a set of rollers

Mandrel is a kind of machining parts used for reinforcement and support

Piercing machine rolls are widely used in construction, decoration, automobiles

There are many types of bearing sleeves, which can be divided

The tension reduction roller is an equipment component used to reduce the diameter

The working principle of straightening rollers is mainly based

The straightening roller changes the straightness of the metal material

Continuous rolls are rolls used in continuous rolling mills for continuous

SERVICE

Custom Roller Solutions

annual production capacity roll

All kinds of rolling products

From raw material processing to the production process, every link is operated in accordance with strict technology, and is equipped with high-quality quality monitoring personnel and complete testing equipment. More than 20 senior technicians, our professional R & D team and engineers create innovative solutions for the needs of our business partners. If you cannot find your specific product, please contact us.

NEWS

Looking forward to establishing long-term cooperation with you

2024/04/24

The difference between continuous roll and cast steel

Roller is a tool for rolling metal materials, and its varieties and manufacturing processes continue to progress with the development of metallurgical technology and rolling equipment. Middle Ages rolling soft non-ferrous metals using low-strength gray cast iron rolls, the middle of the 18th century Britain mastered the production technology of cold hard cast iron rolls for rolling steel plates. In the second half of the 19th century, the progress of European steelmaking technology required rolling larger tonnage of steel ingots, and ordinary cast steel rolls with carbon content of 0.4~0.6 came into being. The use of alloying elements and the introduction of heat treatment in the early 20th century improved the wear resistance and toughness of cast and forged steel hot and cold rolls.

2024/04/24

Working principle of sizing mill

The sizing machine is a kind of equipment used for continuous rolling into straight seam tube billet. Its working principle is to continuously roll strip steel of different specifications into corresponding straight seam tube billet by roller or row roller forming, and then use high frequency induction (or contact) heating to weld the tube billet into straight seam steel pipe. The number of working racks of sizing machine is less, the general number of racks is 5~14, and the total reduction rate is about 3% ~ 7%. Increasing the number of sizing machine frames can expand the product specifications and bring convenience to production. There are many forms of sizing machine, according to the number of rolls can be divided into two-roll, three-roll, four-roll sizing machine; according to the rolling method is divided into longitudinal rolling sizing machine and oblique rolling sizing machine. The service life of the bearing of the sizing machine restricts the service life of the sizing roller box, and the service life of the bearing has a very important relationship with the design, manufacture and installation of the sizing roller box. The main function of the sizing machine is to continuously roll strip steel of different specifications into corresponding straight seam pipe blanks by roller or row roller forming, and weld the pipe blanks into straight seam steel pipes by high frequency induction (or contact) heating.

2024/04/24

Technical requirements for roll of rolling mill

The technical requirements of the rolling mill roll mainly include the following points: First, the main equipment of the rolling mill is composed of the main machine column, which is composed of the main motor, the rolling mill and the transmission machinery. The rolling mill is generally composed of rolls, stands, roll adjustment devices, roll balance positions, roll bearings, etc. The function of the transmission device is to transmit the power of the motor to the roll, and its composition is related to the type and working system of the rolling mill. Secondly, the material selection of the roll is the key, the extensive use of alloying elements is after the world war, which is the rolling equipment towards large-scale, continuous, high-speed, automation development and rolling strength, deformation resistance to increase the performance of the roll put forward higher requirements. In addition, the bending roll technology is also an important part of the rolling mill roll technology, and the hydraulic bending roll device has become an indispensable equipment on various strip rolling mills.

2024/04/24

How much is the hardness of the roll of the piercing machine

The roll is an important part of the piercing machine, and its hardness directly affects the rolling effect in the rolling process. The hardness of the rolls typically ranges between 50-65HRC, while the extra hard rolls have a Shore hardness of about 85-100. The hardness of the roll depends on its use. For example, the plane roll is used in plate and strip rolling mills, and the hardness is usually between 50-65HRC. Groove rolls are used for rolling large, medium and small steel, wire rods and preliminary rolling and billet, and the hardness is usually between 55-65HRC. Special rolls are used in special rolling mills such as steel pipe rolling mills, wheel rolling mills, steel ball rolling mills and perforators, and the hardness is usually between 60-70HRC.