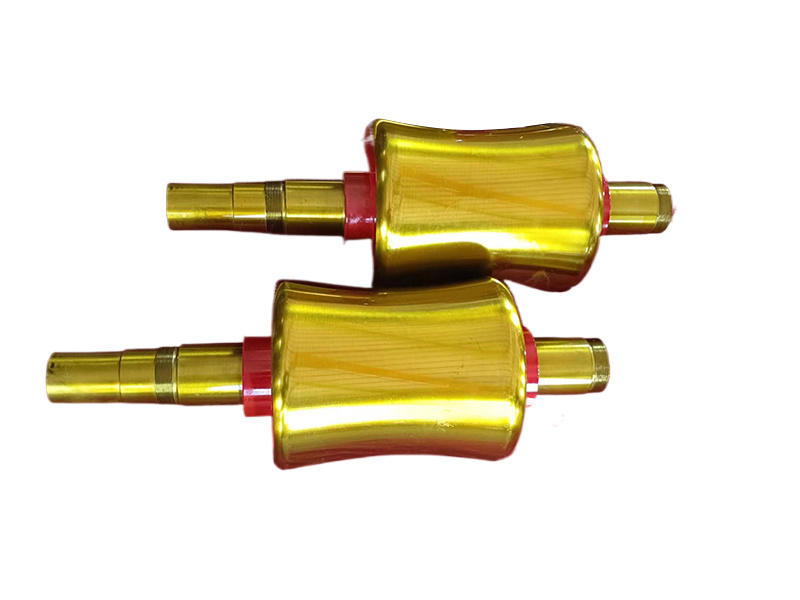

Rolling mill roll

For cold rolling mill, the surface hardness requirements are higher, Shore hardness is about 85~100

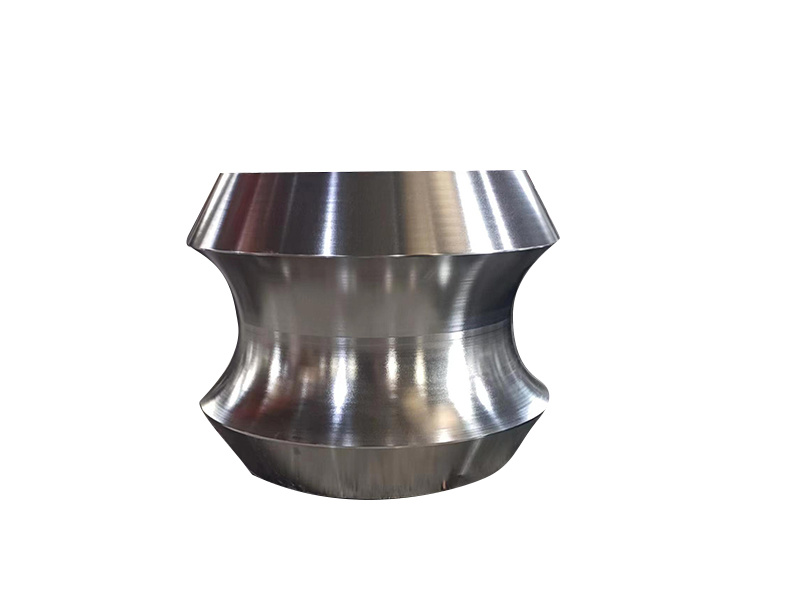

Punch roll is one of the important equipment for steel rolling, its role is to achieve the diameter of the tube under pressure, in order to achieve the purpose of producing different specifications of steel pipe. The parameters such as the distance, inclination and face angle of the roll directly affect the ovality of the deformation area in the rolling process, thus affecting the formation of the hole cavity and the quality of the capillary. At the same time, the material selection and manufacturing process of the roll are also the key factors affecting the rolling effect. In the past five years, China's roll supply has maintained steady growth, of which micro-casting forging perforator rolls and high-speed steel rolls have become the direction of industry research.

The parameters such as the distance, inclination and face angle of the roll directly affect the ovality of the deformation area in the rolling process, thus affecting the formation of the hole cavity and the quality of the capillary. At the same time, the material selection and manufacturing process of the roll are also the key factors affecting the rolling effect. In the past five years, China's roll supply has maintained steady growth, of which micro-casting forging perforator rolls and high-speed steel rolls have become the direction of industry research.

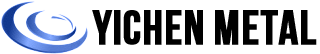

Rolls can be divided into many types according to their shapes and uses, such as vertical rolling mills, two-roll rolling mills, H-beam rolling mills, oblique rolling mills, etc. Among them, the oblique roller mill is suitable for seamless steel pipe perforation machine, the whole machine, etc.

Rolling mill roll is an important equipment for rolling steel, and its performance requirements vary with the type of rolling mill and the conditions of use. The failure mode of rolling mill rolls also varies with the type of rolling mill, so it is necessary to understand the performance and manufacturing process of the current various roll materials in order to formulate the appropriate technical conditions for rolling mill rolls and select the appropriate roll materials. The performance of the rolling mill rolls can be evaluated by the weight of the rolls consumed by rolling 1t of rolled material and the weight of the rolled material reduced per unit roll diameter.