Share

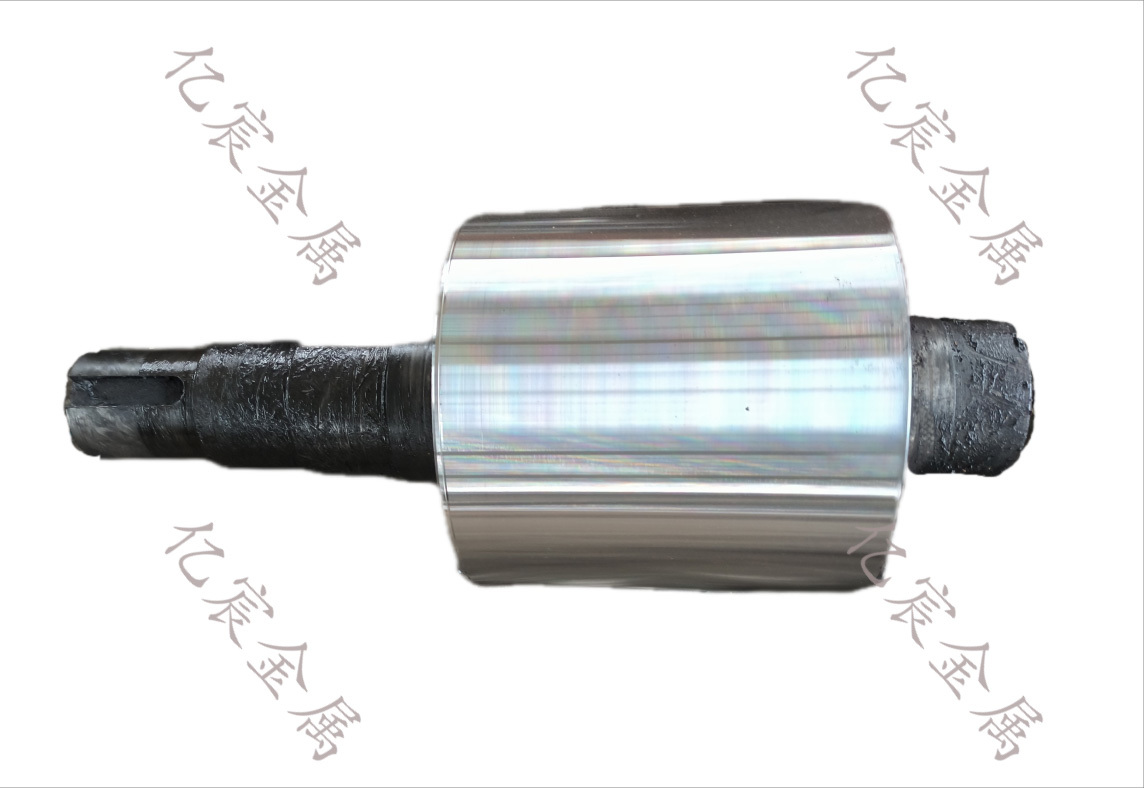

Perforator roll

Product Category

Label

- Product Description

-

Punch roll is one of the important equipment for steel rolling, its role is to achieve the diameter of the tube under pressure, in order to achieve the purpose of producing different specifications of steel pipe. The parameters such as the distance, inclination and face angle of the roll directly affect the ovality of the deformation area in the rolling process, thus affecting the formation of the hole cavity and the quality of the capillary. At the same time, the material selection and manufacturing process of the roll are also the key factors affecting the rolling effect. In the past five years, China's roll supply has maintained steady growth, of which micro-casting forging perforator rolls and high-speed steel rolls have become the direction of industry research.

Yichen Metal

Cangzhou Yichen Metal Rolling Equipment Co., Ltd. is a manufacturing, processing, sales in one of the enterprises. The company mainly produces hot-rolled seamless steel pipe equipment, various alloy ductile iron, casting rolls, high wear resistance and corrosion resistance rolls, high nickel chromium molybdenum roll rings, special steel rolls, mechanical design and manufacturing, etc. Take the lead through the international quality management system 9000, high-tech enterprises, Hebei science and technology small and medium-sized enterprises, various technology patents and other certification. The company has advanced technologies such as smelting, forging, heat treatment and machining, and has international high-tech equipment, intermediate frequency induction furnace melting, resistance furnace heat treatment, casting production line, centrifugal casting production line, bimetal composite casting production line, ultrasonic flaw detection, direct reading spectrum detection, portable metal analyzer, CNC lathe, CNC vertical lathe, CNC gantry milling, large lathe and other mechanical production equipment.

Certification

Perforator roll

Product Category

Label

Inquiry

Note: Please leave your email and mobile phone number, our professionals will contact you as soon as possible!

Recommend products