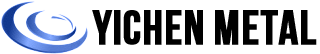

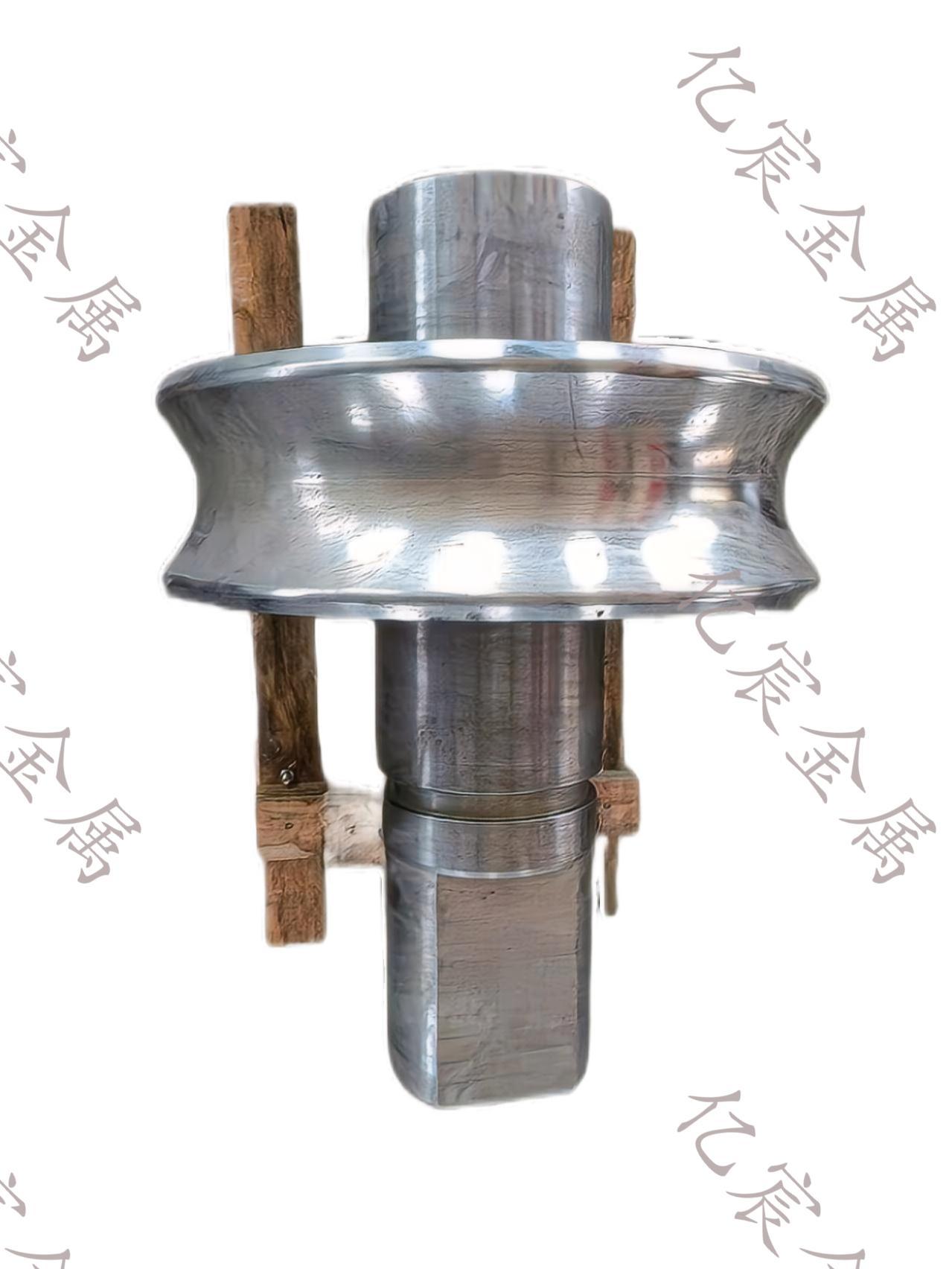

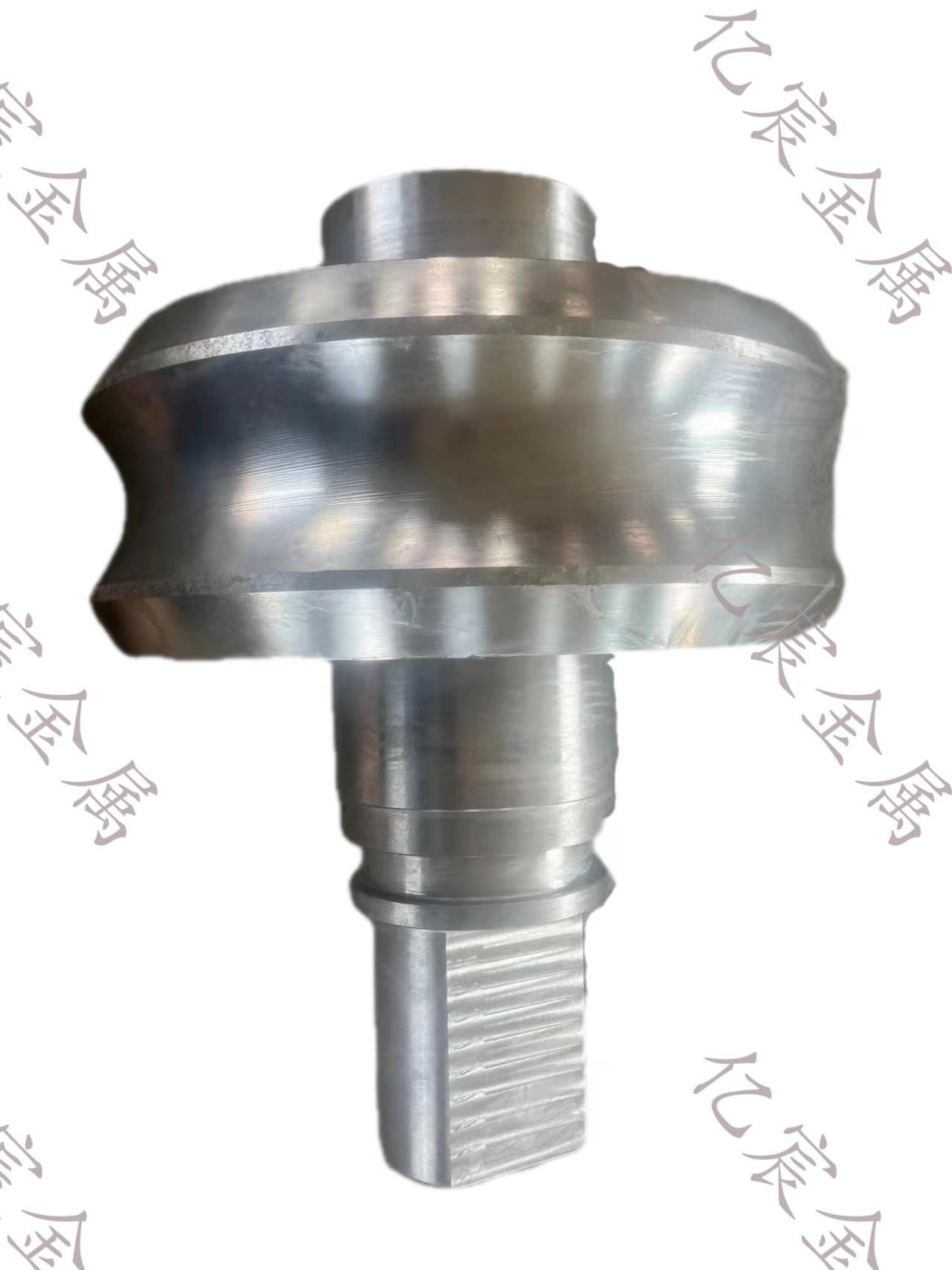

Continuous roll

Roll material selection is the key, the extensive use of alloying elements is after the world war, which is the rolling equipment towards large-scale, continuous, high-speed, automation development and rolling strength, deformation resistance to increase the performance of the roll put forward higher requirements. In addition, the bending roll technology is also an important part of the rolling mill roll technology, and the hydraulic bending roll device has become an indispensable equipment on various strip rolling mills.

Roller is a tool for rolling metal materials, and its varieties and manufacturing processes continue to progress with the development of metallurgical technology and rolling equipment. Middle Ages rolling soft non-ferrous metals using low-strength gray cast iron rolls, the middle of the 18th century Britain mastered the production technology of cold hard cast iron rolls for rolling steel plates. In the second half of the 19th century, the progress of European steelmaking technology required rolling larger tonnage of steel ingots, and ordinary cast steel rolls with carbon content of 0.4~0.6 came into being. The use of alloying elements and the introduction of heat treatment in the early 20th century improved the wear resistance and toughness of cast and forged steel hot and cold rolls.