2024/04/24

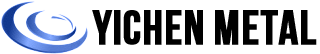

The difference between continuous roll and cast steel

Roller is a tool for rolling metal materials, and its varieties and manufacturing processes continue to progress with the development of metallurgical technology and rolling equipment. Middle Ages rolling soft non-ferrous metals using low-strength gray cast iron rolls, the middle of the 18th century Britain mastered the production technology of cold hard cast iron rolls for rolling steel plates. In the second half of the 19th century, the progress of European steelmaking technology required rolling larger tonnage of steel ingots, and ordinary cast steel rolls with carbon content of 0.4~0.6 came into being. The use of alloying elements and the introduction of heat treatment in the early 20th century improved the wear resistance and toughness of cast and forged steel hot and cold rolls.

2024/04/24

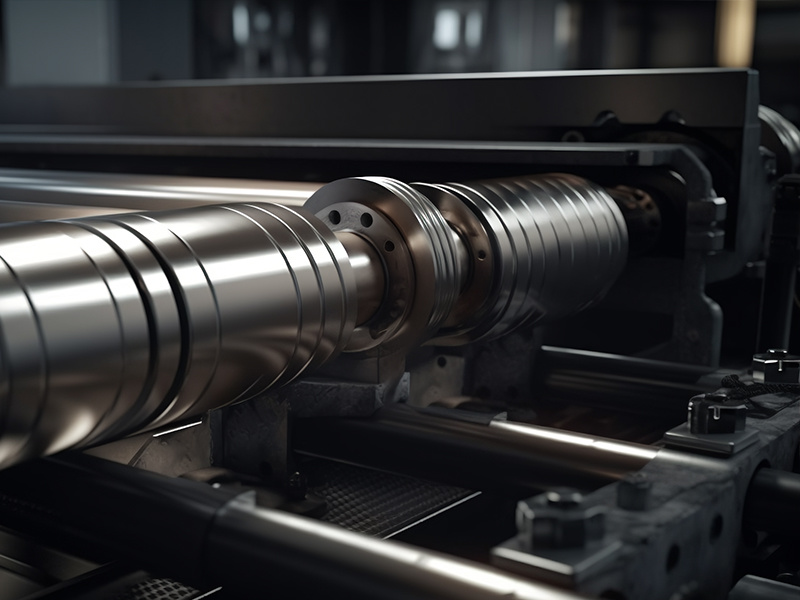

Working principle of sizing mill

The sizing machine is a kind of equipment used for continuous rolling into straight seam tube billet. Its working principle is to continuously roll strip steel of different specifications into corresponding straight seam tube billet by roller or row roller forming, and then use high frequency induction (or contact) heating to weld the tube billet into straight seam steel pipe. The number of working racks of sizing machine is less, the general number of racks is 5~14, and the total reduction rate is about 3% ~ 7%. Increasing the number of sizing machine frames can expand the product specifications and bring convenience to production. There are many forms of sizing machine, according to the number of rolls can be divided into two-roll, three-roll, four-roll sizing machine; according to the rolling method is divided into longitudinal rolling sizing machine and oblique rolling sizing machine. The service life of the bearing of the sizing machine restricts the service life of the sizing roller box, and the service life of the bearing has a very important relationship with the design, manufacture and installation of the sizing roller box. The main function of the sizing machine is to continuously roll strip steel of different specifications into corresponding straight seam pipe blanks by roller or row roller forming, and weld the pipe blanks into straight seam steel pipes by high frequency induction (or contact) heating.

2024/04/24

Technical requirements for roll of rolling mill

The technical requirements of the rolling mill roll mainly include the following points: First, the main equipment of the rolling mill is composed of the main machine column, which is composed of the main motor, the rolling mill and the transmission machinery. The rolling mill is generally composed of rolls, stands, roll adjustment devices, roll balance positions, roll bearings, etc. The function of the transmission device is to transmit the power of the motor to the roll, and its composition is related to the type and working system of the rolling mill. Secondly, the material selection of the roll is the key, the extensive use of alloying elements is after the world war, which is the rolling equipment towards large-scale, continuous, high-speed, automation development and rolling strength, deformation resistance to increase the performance of the roll put forward higher requirements. In addition, the bending roll technology is also an important part of the rolling mill roll technology, and the hydraulic bending roll device has become an indispensable equipment on various strip rolling mills.

2024/04/24

How much is the hardness of the roll of the piercing machine

The roll is an important part of the piercing machine, and its hardness directly affects the rolling effect in the rolling process. The hardness of the rolls typically ranges between 50-65HRC, while the extra hard rolls have a Shore hardness of about 85-100. The hardness of the roll depends on its use. For example, the plane roll is used in plate and strip rolling mills, and the hardness is usually between 50-65HRC. Groove rolls are used for rolling large, medium and small steel, wire rods and preliminary rolling and billet, and the hardness is usually between 55-65HRC. Special rolls are used in special rolling mills such as steel pipe rolling mills, wheel rolling mills, steel ball rolling mills and perforators, and the hardness is usually between 60-70HRC.

2024/04/24

Working principle of coal mill in thermal power plant

The coal mill in a thermal power plant is an important equipment. Its working principle is to grind coal into powder for easy combustion. Coal mills usually use rotation, inertia, gravity and other separation principles for separation, but this separation method is not thorough enough, so it is necessary to use a dynamic separator, driven by a motor, to improve the separation efficiency. In addition, the combustion system of thermal power plants also includes coal conveying, coal grinding, coarse and fine separation, powder discharge, powder feeding, boiler, dust removal, desulfurization and other links.

2024/04/24

Method of reducing wear of support roll of levelling machine

The wear of the support roller of the leveler is one of the common problems in the production of steel rolling. In order to reduce the wear of the support roller, the following measures can be taken:(1) select appropriate leveling lubricating medium and leveling process parameters to reduce friction and wear;(2) control the vibration of the work roller and the support roller to reduce the vibration pattern;(3) control the roll change cycle to prevent the generation of vibration pattern in advance;(4) regularly replace the roller and the support roller to ensure the accuracy of the equipment;(5) regular maintenance, ensure the parallelism and levelness of uncoiling, winding, roller, anti-wrinkle and anti-chattering rollers;(6) Optimize the roll shape configuration of the four-roll CVC leveler, and the improved roll shape configuration performs well in improving the shape control ability and roll shape self-retention;(7) Design a new support roll shape combined with the characteristics of CVC support roll and VCR support roll, which effectively improves the contact pressure distribution between rolls, the stiffness of the roll gap is improved, and the control of the strip section is more stable.

2024/04/24

The core rod is a material used for composite insulators, which is mainly composed of a glass fiber body and a resin, and is formed by heating and curing through a mold. The material of the mandrel has a great influence on the acid corrosion resistance of the product, so it is necessary to make a reasonable choice according to the material characteristics of the mandrel. In addition, the pultrusion process of the mandrel also needs to be optimized to improve the overall electromechanical properties of the mandrel.

2024/04/24

Sizing roller is an important part of rolling equipment. Its main uses include: 1) continuous rolling of strip steel of different specifications into corresponding straight seam tube blanks through roller or row roller forming; 2) micro-reduction and billet rolling of welded pipes in the sizing section to realize the size adjustment of welded pipes; 3) Provide driving force for the operation of welded pipes, prevent the welded pipe from sticking or stagnation in the sizing section. In addition, the use of the sizing roller also needs to be noted that the adjustment of its axial position should remain stable to avoid affecting the size of the welded pipe.

2024/04/24

What heating is used for hot rolling rolls of rolling mills

Rolling Mill Hot rolling rolls are usually heated using a furnace. The working temperature of the hot rolling roll is usually between 700 ℃ and 800 ℃, and it needs to bear a strong rolling force. At the same time, the surface must bear the wear of the rolled material, and it is repeatedly heated by the hot rolled material and cooled by the cooling water. Thermal fatigue effect with large temperature changes. Therefore, the hot rolling roll material must have high hardenability, low thermal expansion coefficient, high thermal conductivity and high high temperature yield strength and wear resistance. High chromium cast iron rolls have good thermal crack resistance, because a dense and tough chromium oxide film is formed on the surface of the roll, which can reduce the number and depth of thermal cracks.

2024/04/24

The use of the roll of the perforator.

The roll is an important part of the piercing machine. Its main uses include: unscrewing the roll cooling and lubrication system from the connection of the drum; Open the universal joint bolt, and use the upper and lower brackets to smoothly lift the universal joint out, subject to not affecting the roll lifting and placing; Use a crane to smoothly lift the upper and lower drums out and put in; Fasten each connection, restore the original state, and adjust the hole pattern to a suitable position.