Share

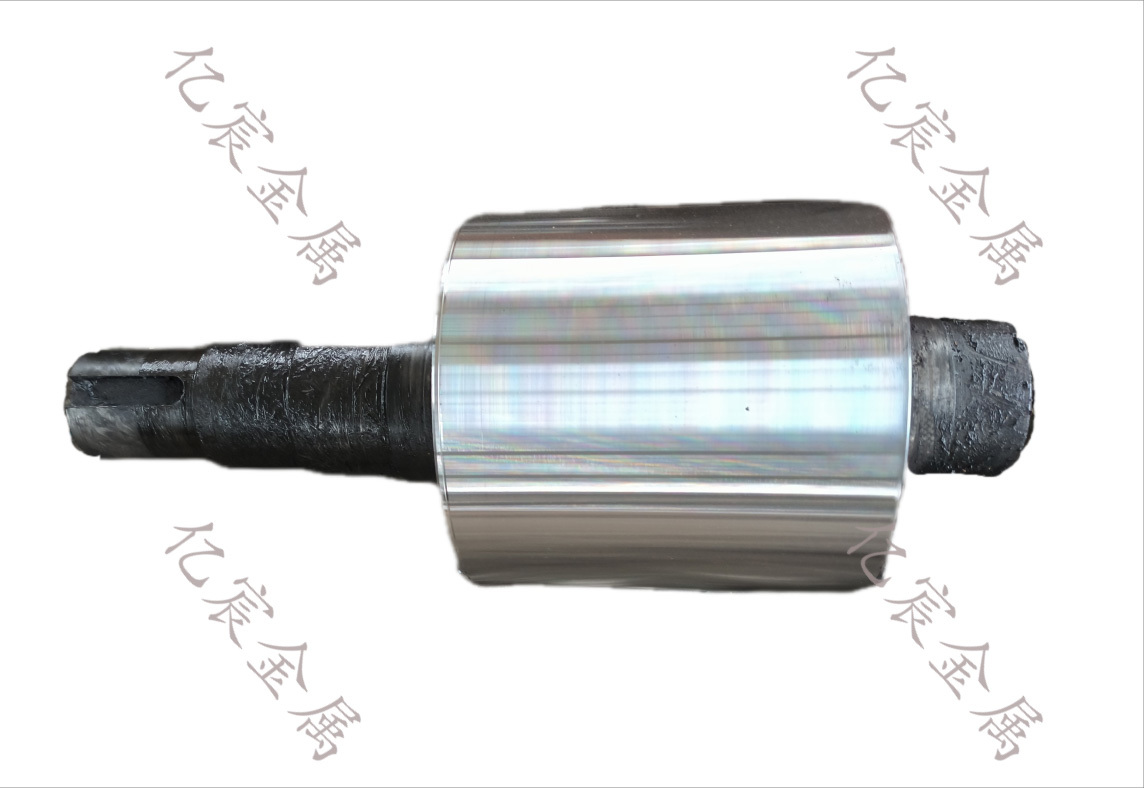

Sizing roll

Product Category

Label

- Product Description

-

The working principle of the sizing roller is to use a set of rollers with equal diameter to form plates or pipes. In the processing process, it can uniformly and accurately control the molding diameter and thickness, so as to achieve high-precision, high-efficiency and high-quality molding effects. Specifically, the roller diameter, the feeding method of the plate (insulated feeding or co-feeding), the roller profile (high flatness, high precision, stable shape and smooth surface), the roller material and processing accuracy will affect the forming effect of the sizing roller.

The sizing roller is widely used in the steel pipe production industry and is one of the key factors to ensure the quality and production efficiency of steel pipes. During use, it is necessary to regularly inspect and maintain the sizing roller, including cleaning the surface of the roller, checking the wear, and replacing the severely worn roller. In addition, it is also necessary to pay attention to maintaining the smooth operation of the sizing roller to avoid abnormal operating conditions such as too fast, too slow, and unstable. These measures help to extend the service life of sizing rollers, improve production efficiency and reduce production costs.

Yichen Metal

Cangzhou Yichen Metal Rolling Equipment Co., Ltd. is a manufacturing, processing, sales in one of the enterprises. The company mainly produces hot-rolled seamless steel pipe equipment, various alloy ductile iron, casting rolls, high wear resistance and corrosion resistance rolls, high nickel chromium molybdenum roll rings, special steel rolls, mechanical design and manufacturing, etc. Take the lead through the international quality management system 9000, high-tech enterprises, Hebei science and technology small and medium-sized enterprises, various technology patents and other certification. The company has advanced technologies such as smelting, forging, heat treatment and machining, and has international high-tech equipment, intermediate frequency induction furnace melting, resistance furnace heat treatment, casting production line, centrifugal casting production line, bimetal composite casting production line, ultrasonic flaw detection, direct reading spectrum detection, portable metal analyzer, CNC lathe, CNC vertical lathe, CNC gantry milling, large lathe and other mechanical production equipment.

Certification

Sizing roll

Product Category

Label

Inquiry

Note: Please leave your email and mobile phone number, our professionals will contact you as soon as possible!

Recommend products